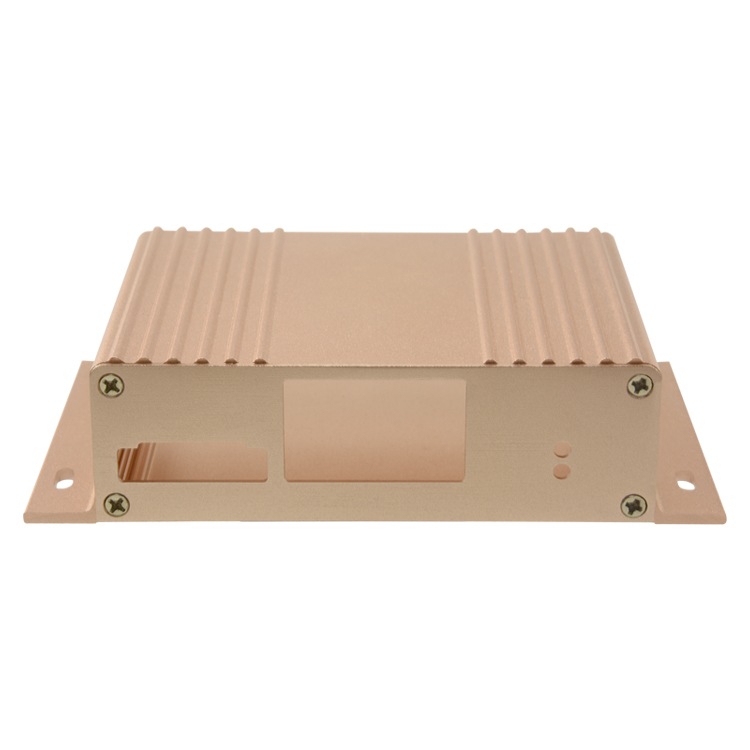

Now human life is more and more inseparable from two words "intelligent ",

our company CNC precision machining intelligent access control shell has been

praised, our precision machining intelligent access control shell material is

good, The aluminum alloy used in the product comes from high quality raw

materials imported from Korea. You can also fit and give professional

advice.

product description:

|

name:

|

Face recognition machine shel

|

|

material:

|

Aluminum alloy 6061

|

|

technology:

|

CNC Precision Machining、EDM process

|

|

product specification:

|

Length arbitrary customization

|

|

Product plus:

|

Can be processed according to customer requirements

|

|

Product colour:

|

Customizable to customer requirements

|

|

surface treatment:

|

Sand spraying oxidation, wire drawing oxidation, secondary oxidation and spraying treatment.

|

|

tolerance:

|

+/-0.01mm

|

|

delivery time :

|

5 days

|

|

quality control :

|

100% testing

|

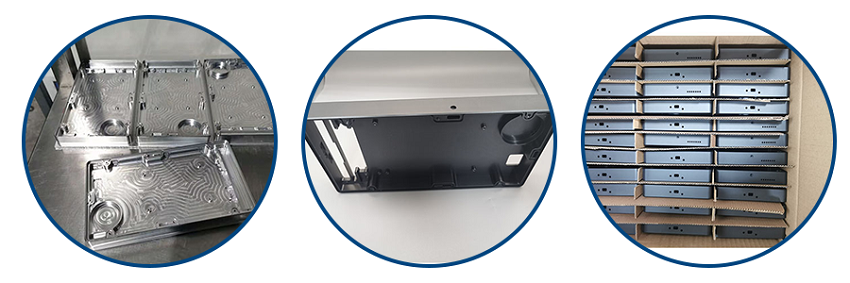

Advantages of CNC Precision Machining Aluminum Outer Shells:

Delivery is fast:Many types of CNC machine tools, can simultaneously

achieve a variety of processes (such as drilling, tapping), a variety of surface

treatment, save processing cycle, Huanyu precision production of high-precision

parts in 3 working days.

High accuracy:With a number of imported CNC processing equipment, accuracy

can reach tolerance /-0.05-0.01 mm.

Number not limited:Whether proofing 1 or 1000 small batch customization,

can be satisfied.

Materials not available:Select all kinds of metal materials available on

the market to meet customized needs.

pre-sale service:

Before cooperation, there are professional project evaluation engineers

docking, through in-depth communication to do a good job of product structure

optimization, to confirm the correct selection of materials and processes, to

give customers reasonable advice, reduce communication in the manufacturing

process, Effectively avoid problems in production.

Sales services:

Cooperation has exclusive engineer and business specialist docking, project

manager to process control, active communication and interaction, timely

detection of problems, time-limited communication, for production delivery.

After service:

After the sale of any problems encountered customer requirements, there are

professional QE and engineering personnel docking, the day response; and timely

confirmation with customers, discuss, solve problems, to meet customer

production needs.

FAQ:

CNC what materials will be used to process robot parts?

There are many kinds of robot parts, so there are many kinds of materials used. Since the establishment of Huanyu Precision ,475 kinds of materials have been processed, and the spectral analyzer has been equipped to ensure the authenticity of raw materials. According to Huanyu precision understanding, CNC processing robot parts common materials are: aluminum alloy, magnesium alloy, stainless steel, copper alloy and all kinds of steel.

CNC precision machining robot parts can do what surface treatment?

Many robot parts will do some surface treatment after processing, enhance the corrosion resistance, wear resistance and other properties of the parts to improve service life, or in order to attract more people's attention in the exhibition, priority to occupy the market. CNC precision machining robot parts common surface treatment: spraying, blackening, electroplating, oxidation, radium carving, screen printing and so on.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик